In the world of electrical systems, conduit fittings, and wire conduits play a crucial role in providing protection and organization. Understanding the different types of conduit fittings and wire conduits is essential for any electrical project. This article will delve into the various aspects of conduit fittings and wire conduits, from their importance to installation tips and troubleshooting common issues.

Understanding Conduit Fittings

Conduit box fittings are essential components that connect and secure conduit pipes together. They ensure a safe and reliable electrical system by preventing wire damage and shielding against moisture, chemicals, and physical impact. Without conduit fittings, electrical systems would be vulnerable to various hazards, compromising both safety and functionality.

When it comes to electrical installations, attention to detail is crucial. Conduit fittings play a vital role in maintaining the integrity of the entire system. By securely connecting conduit pipes, they provide a stable pathway for electrical wires, ensuring that they are properly protected and organized.

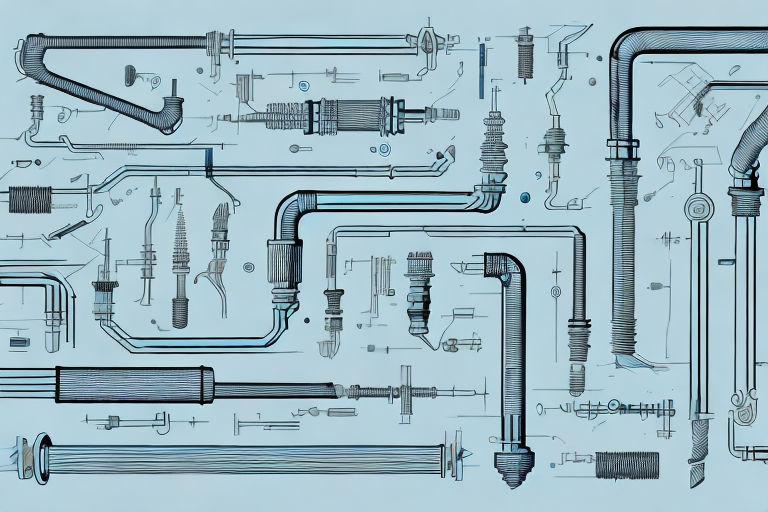

Types of Conduit Fittings

Conduit fittings come in various shapes and sizes, designed to accommodate different types of conduits and installation requirements. Understanding the different types of conduit fittings is essential for selecting the right ones for your specific needs.

One common type of conduit fitting is the conduit connector. These fittings establish a secure connection between two conduit pipes, ensuring that they remain firmly joined together. This is particularly important in situations where vibrations or movements may occur, as it prevents the pipes from disconnecting and potentially causing electrical disruptions.

Bushings are another type of conduit fitting that deserves attention. These fittings serve to protect wires from rough edges and sharp corners where the conduit enters a junction box. By providing a smooth transition between the conduit and the box, bushings minimize the risk of wire damage and ensure a tidy and organized installation.

Couplings, on the other hand, are used to join two conduit pipes of the same diameter. They provide a secure and reliable connection, allowing for the seamless continuation of the conduit path. Couplings are particularly useful when extending conduit runs or when connecting different sections of a larger electrical system.

The Role of Conduit Fittings in Electrical Systems

Conduit fittings play a crucial role in ensuring the overall functionality and safety of electrical systems. By properly installing conduit fittings, the electrical wiring is shielded from external elements, reducing the risk of electrical shocks and short circuits.

One of the primary functions of conduit fittings is to protect electrical wires from moisture. Moisture can be a significant threat to electrical systems, as it can lead to corrosion, insulation degradation, and even electrical malfunctions. Conduit fittings act as a barrier, preventing moisture from seeping into the conduit and reaching the wires, thus safeguarding the entire system. Click here to read about Why Engage a Buyers Agent in Brisbane?

Furthermore, conduit fittings provide support and stability to the conduit pipes. They help distribute the weight of the pipes and prevent sagging or bending, ensuring that the electrical wires inside are not subjected to unnecessary strain. This support is especially crucial in installations where conduit pipes are exposed to harsh environmental conditions or heavy loads.

In addition to protection and support, conduit fittings also offer flexibility in electrical systems. They allow for easier maintenance and future modifications, as conduit pipes can be easily disconnected and reconnected using the appropriate fittings. This flexibility is particularly advantageous in situations where system upgrades or changes are necessary, as it minimizes the need for extensive rewiring.

Selecting the Right Conduit Fittings

Choosing the right conduit fittings is a critical step in any electrical installation. Several factors need to be considered to ensure that the selected fittings are compatible with the conduit type, application, and environmental conditions.

One important factor to consider is the temperature of the installation environment. Some conduit fittings are specifically designed to withstand high temperatures, making them suitable for applications where heat resistance is essential. Similarly, if the installation is exposed to low temperatures, selecting fittings that can withstand freezing conditions is crucial to prevent cracking or other forms of damage.

Moisture is another factor that should not be overlooked. In environments where moisture is present, such as outdoor installations or areas prone to water exposure, it is essential to choose conduit fittings that offer excellent moisture resistance. This will ensure that the electrical system remains protected, even in challenging conditions.

Corrosive substances are yet another consideration when selecting conduit fittings. In environments where chemicals or corrosive agents are present, it is crucial to choose fittings that are resistant to these substances. This will prevent premature deterioration of the fittings and ensure the long-term reliability of the electrical system.

Given the complexity of selecting the right conduit fittings, consulting with a professional electrician is highly recommended. Electricians have the expertise and experience to assess the specific requirements of an electrical installation and provide guidance on the most suitable conduit fittings to use. By seeking professional advice, you can ensure that your electrical system is equipped with the right fittings for optimal performance and safety.

Diving into Wire Conduits

Wire conduits, also known as electrical conduits, are protective enclosures that house electrical wires and cables. They serve as a pathway for safe wire installation, shielding the wires from damage and maintaining organization within the electrical system.

When it comes to electrical systems, safety is paramount. Wire conduits play a crucial role in ensuring the protection of electrical wires from external factors such as moisture, dirt, and physical impact. By acting as a barrier, wire conduits reduce the risk of short circuits and electrical fires, providing peace of mind to homeowners and professionals alike.

The Importance of Wire Conduits

Wire conduits provide numerous benefits, making them an essential component of any electrical system. Let’s take a closer look at some of these advantages:

- Protection: Wire conduits safeguard electrical wires from external factors such as moisture, dirt, and physical impact, reducing the risk of short circuits and electrical fires. This protection is especially crucial in environments where wires are exposed to harsh conditions or heavy machinery.

- Organization: By containing wires within conduits, the electrical system remains tidy and easily maintainable. It also minimizes the risk of accidental damage caused by tangled wires. With organized wire conduits, troubleshooting and repairs become more efficient, saving time and effort.

- Flexibility: Wire conduits allow for future modifications and additions to the electrical system without the need for extensive rewiring. This flexibility is particularly valuable in commercial and industrial settings where electrical systems often undergo changes due to evolving needs.

Different Materials Used in Wire Conduits

Wire conduits are available in various materials, each with its own advantages and limitations. The choice of material depends on factors such as the environment, application, and budget. Here are some common materials used in wire conduits:

- Metallic conduits: Metallic conduits, such as steel or aluminum, provide excellent durability and protection against physical impact. They are commonly used in industrial and commercial settings where the electrical system may be exposed to heavy machinery or potential hazards. Metallic conduits are known for their strength and ability to withstand harsh conditions.

- Non-metallic conduits: Non-metallic conduits, made from materials like PVC or fiberglass, are lightweight, flexible, and resistant to corrosion. They are often used in residential applications where ease of installation and cost-effectiveness are important factors. Non-metallic conduits are also known for their versatility and ability to adapt to various wiring needs.

Installation Tips for Wire Conduits

Proper installation of wire conduits is crucial for maximizing their effectiveness and ensuring a safe electrical system. Here are some important tips to consider during the installation process:

- Plan the layout: Before installation, carefully plan the conduit route to ensure efficient wire organization and minimal bends. Proper planning can prevent unnecessary complications and ensure a clean and organized electrical system.

- Measure and cut accurately: Precise measurements and clean cuts are essential for a proper fit and ease of wiring installation. Accurate measurements ensure that the conduits fit securely and allow for smooth wire routing.

- Secure conduits properly: Use appropriate fasteners and supports to ensure the conduits are securely attached to walls or other surfaces. Proper securing prevents the conduits from shifting or becoming loose, maintaining the integrity of the electrical system.

- Follow electrical codes: Adhere to the relevant electrical codes and regulations to maintain compliance and safety standards. Electrical codes exist to ensure the safety of individuals and properties, so it is crucial to follow them during the installation of wire conduits.

By following these installation tips, you can ensure the optimal performance and longevity of your wire conduits, creating a safe and reliable electrical system.

Advanced Topics in Electrical Conduits

As technology evolves, so do electrical conduits. It’s crucial to stay informed about advancements and safety considerations in conduit installation.

Electrical conduits play a vital role in providing a safe and reliable pathway for electrical wiring. They protect the wires from physical damage, moisture, and other environmental factors that could compromise the integrity of the electrical system. In this article, we will explore the evolution of electrical conduits, safety considerations in conduit installation, and future trends in conduit technology.

The Evolution of Electrical Conduits

Over the years, electrical conduits have undergone significant improvements. Modern conduits now include features such as enhanced flexibility, better resistance to environmental factors, and improved ease of installation.

One notable advancement in conduit technology is the development of flexible conduits. Unlike rigid conduits, flexible conduits allow for easier installation in tight spaces and around corners. They are made of materials like PVC, metal, or liquid-tight materials, providing excellent protection for the electrical wiring.

Another improvement is the introduction of conduits with enhanced resistance to environmental factors. These conduits are designed to withstand extreme temperatures, moisture, chemicals, and UV radiation. They ensure the longevity and reliability of the electrical system, even in harsh conditions.

Furthermore, modern conduits offer improved ease of installation. Manufacturers have developed innovative features such as snap-on connectors, pre-threaded ends, and quick-lock mechanisms, making the installation process faster and more efficient.

Safety Considerations in Conduit Installation

When installing electrical conduits, safety should always be a top priority. Some important safety considerations include proper grounding, ensuring adequate ventilation for heat dissipation, and using suitable protective equipment during installation.

Proper grounding is essential to protect against electrical faults and ensure the safety of individuals and equipment. Grounding provides a path for electrical current to flow safely into the ground, preventing the buildup of dangerous voltages. It is crucial to follow the local electrical codes and guidelines for grounding requirements during conduit installation.

Adequate ventilation is another critical safety consideration. Electrical conduits generate heat, especially when carrying high currents. Proper ventilation allows for heat dissipation, preventing overheating and potential fire hazards. Installers should ensure that conduits are not obstructed and have sufficient airflow to maintain safe operating temperatures.

During conduit installation, it is important to use suitable protective equipment to minimize the risk of injuries. This includes wearing gloves, safety glasses, and appropriate clothing to protect against electrical shocks, cuts, and other potential hazards. Following safety protocols and using the right tools can significantly reduce the likelihood of accidents during installation.

Future Trends in Conduit Technology

The future of electrical conduits is promising, with advancements in technology aiming for more efficient and sustainable solutions. Some emerging trends include the integration of smart features, such as sensors and monitoring capabilities, to enhance system reliability and energy efficiency.

Smart conduits equipped with sensors can detect abnormalities in the electrical system, such as voltage fluctuations or temperature variations. This real-time monitoring allows for proactive maintenance and early detection of potential issues, minimizing downtime and improving overall system performance.

Furthermore, smart conduits can be integrated with building automation systems, enabling remote control and monitoring of the electrical system. This level of automation enhances energy efficiency by optimizing power consumption based on real-time demand and reducing wastage.

Another trend in conduit technology is the development of sustainable materials. Manufacturers are exploring eco-friendly alternatives to traditional conduit materials, such as bio-based plastics or recycled materials. These sustainable conduits aim to reduce environmental impact while maintaining the required performance and safety standards.

In conclusion, staying informed about advancements and safety considerations in electrical conduit installation is crucial for professionals in the field. The evolution of electrical conduits has brought about improved flexibility, resistance to environmental factors, and ease of installation. Safety considerations, such as proper grounding, ventilation, and protective equipment, are essential to ensure a safe and reliable electrical system. Looking ahead, the future of conduit technology holds exciting possibilities with the integration of smart features and sustainable materials.

Troubleshooting Common Conduit Issues

Despite the best installation practices, conduit issues may arise over time. Learning to identify and address these issues is essential for maintaining the integrity of the electrical system.

Identifying Conduit Problems

Common conduit problems include leaks, corrosion, or physical damage. Regular inspections can help identify these issues before they lead to more significant problems, such as wire damage or electrical malfunctions.

Repairing and Replacing Conduit Components

If conduit problems are detected, timely repairs or replacements are necessary. It is essential to follow proper procedures and use suitable replacement components to ensure the integrity of the electrical system.

Preventive Measures for Conduit Issues

Prevention is always better than cure. Taking preventive measures can significantly reduce the likelihood of conduit issues. These include regular inspections, applying protective coatings, and implementing proper maintenance practices.

As you can see, conduit fittings and wire conduits are critical elements in electrical systems. Understanding their types, roles, and installation techniques is essential for safe and efficient electrical projects. By staying informed about the latest advancements and troubleshooting common issues, you can ensure the longevity and reliability of your electrical system.